Electronic and software upgrades for T35 and T35S

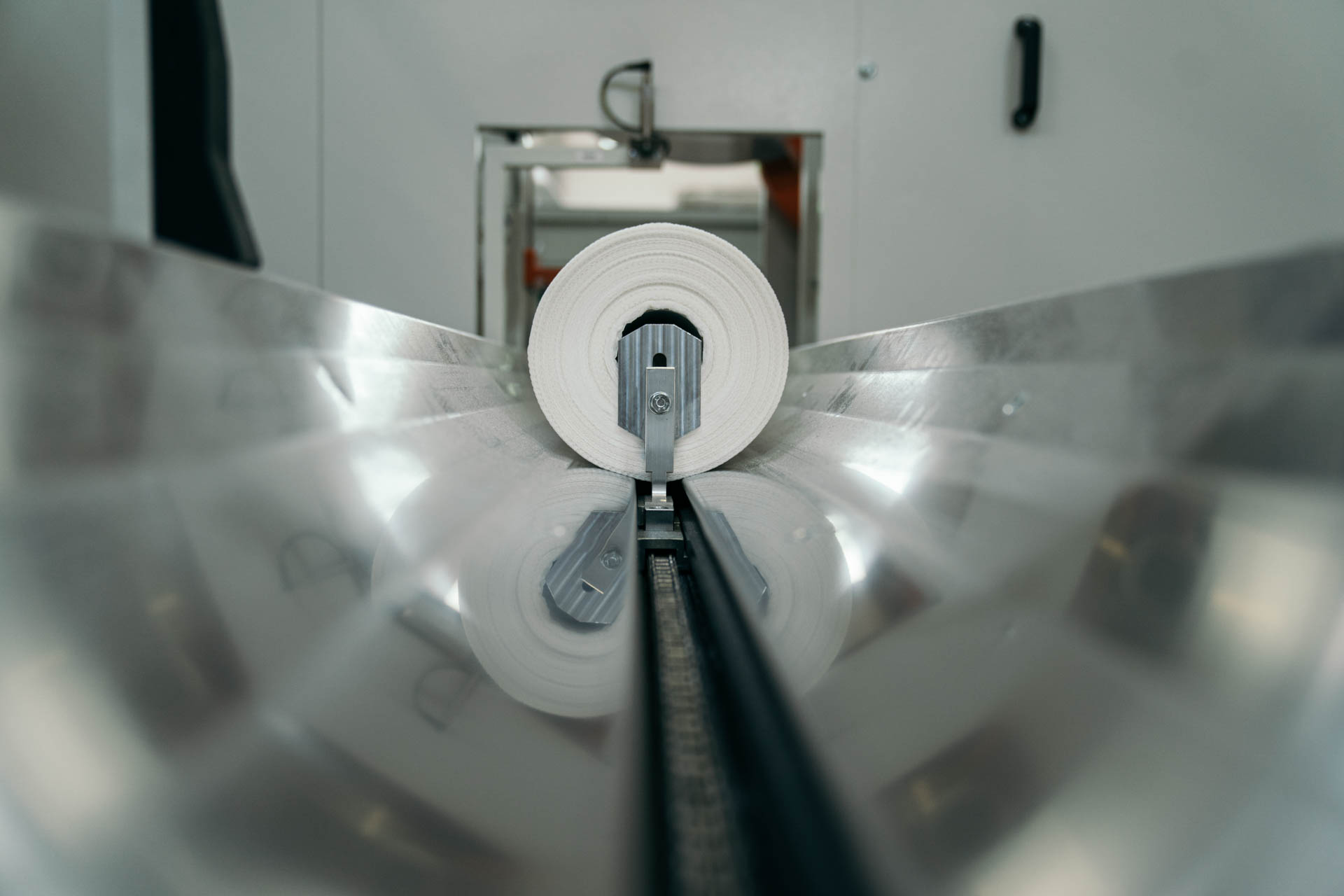

Unico365 Automatic Blade Compensation

An upgrade introduced by Unico365 technology that allows logsaw to automatically control the cutting blade arm angle to compensate for diameter reduction during normal use. The upgrade involves the installation of a sensor and associated electronics, as well as software modifications within the HMI&PLC system.

Unico365 E-Stop Management

This upgrade, also known as “Open Door Management”, involves revising the blade software of T35 and T35S saws. In case of an E-Stop or opening a door during the normal cutting cycle, instead of having to discard a partially cut log, the blade can be restarted to resume cutting the log from the exact point of interruption. This results in obvious advantages in terms of productivity and waste reduction.