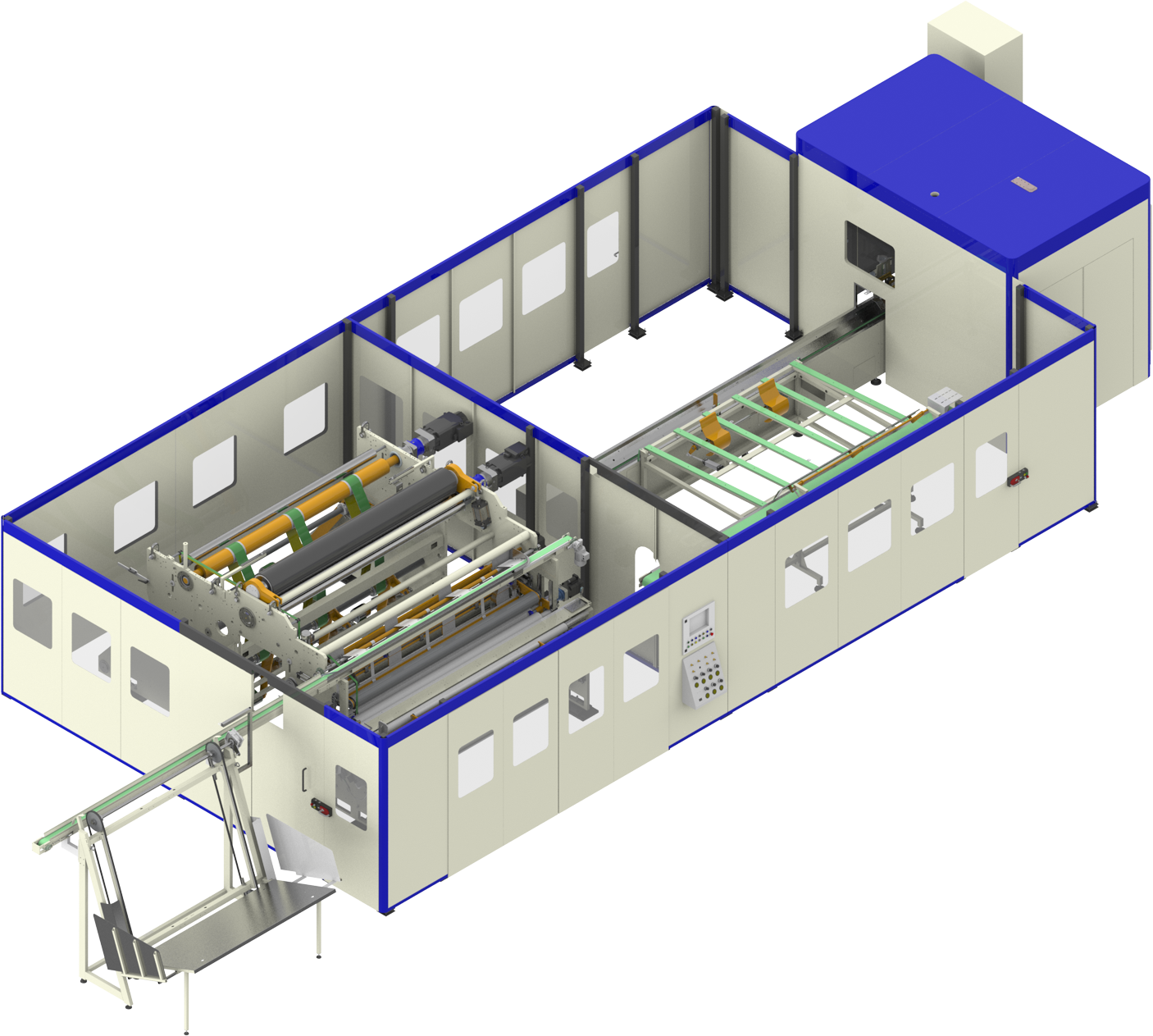

S-Line

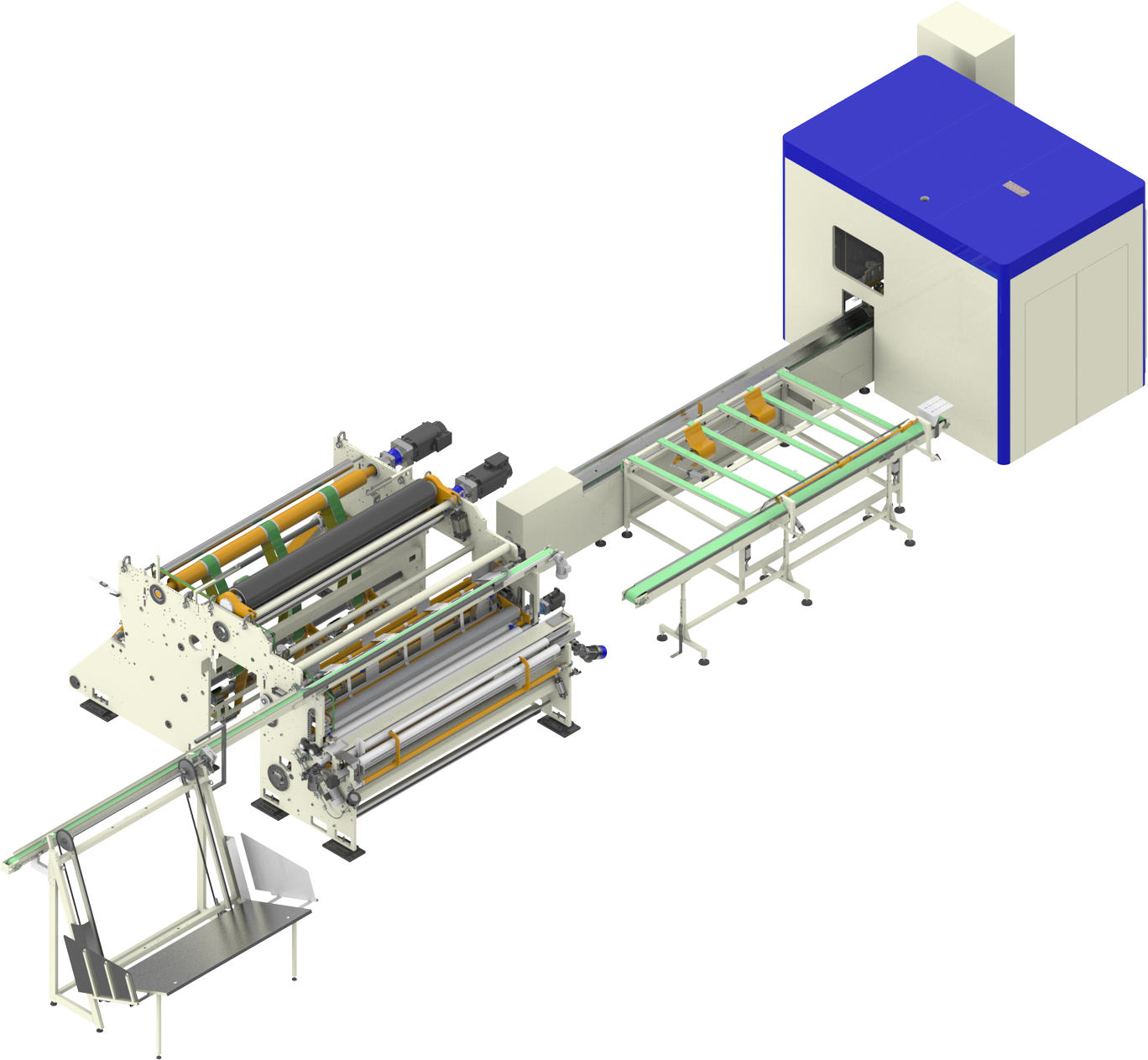

Boost your productivity and efficiency coefficients. S-Line is more efficient, more flexible, more sustainable, easier to use and maintain.

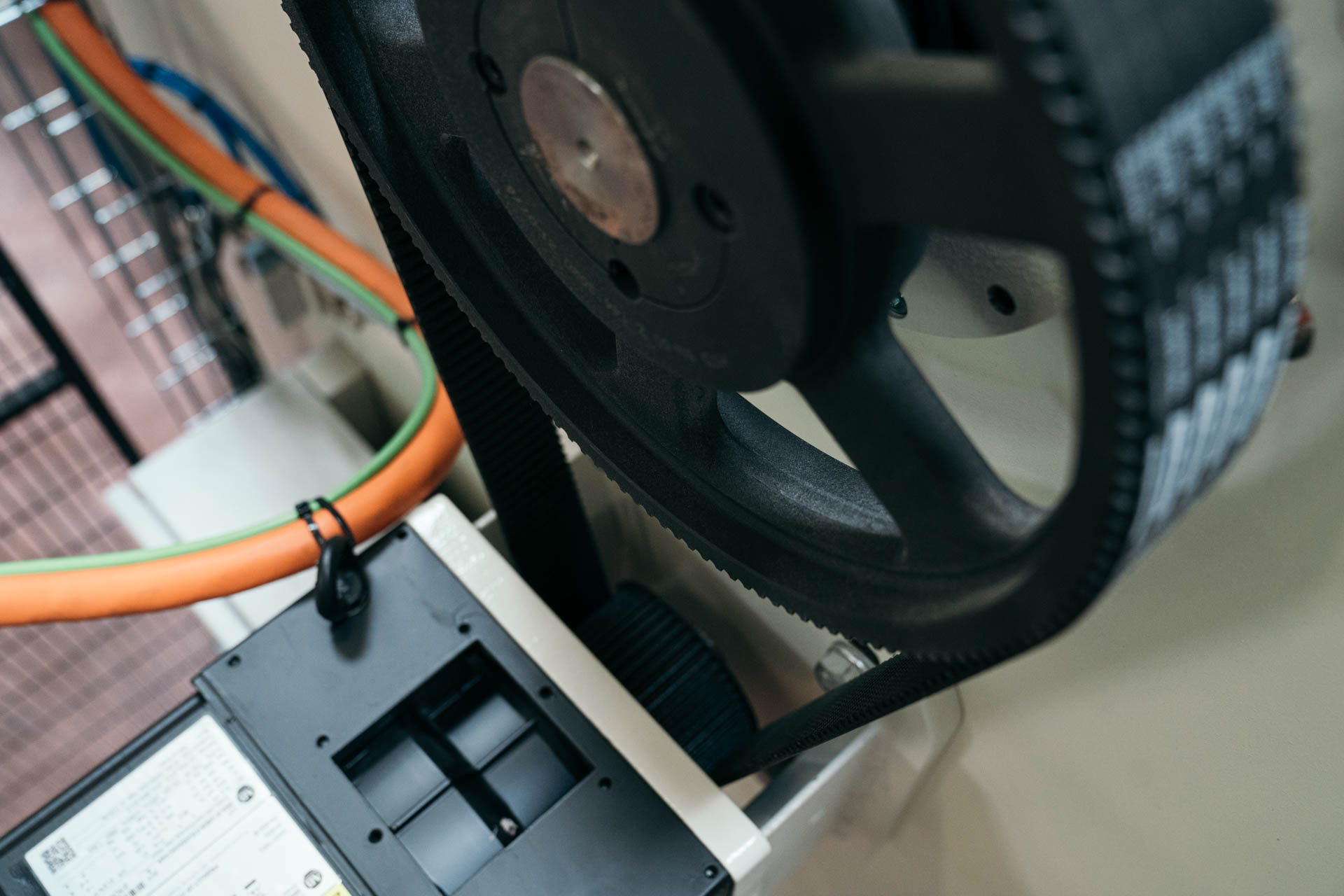

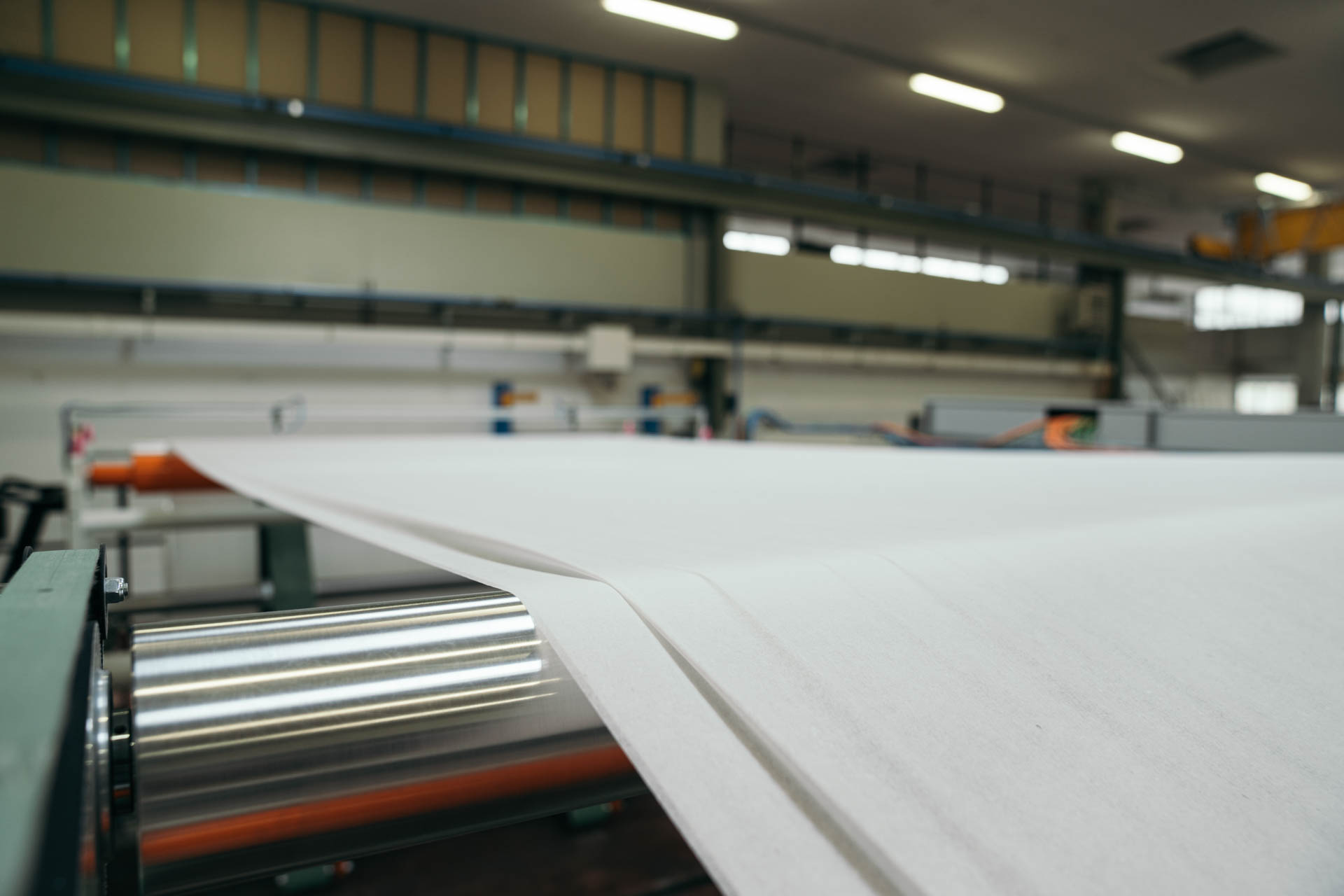

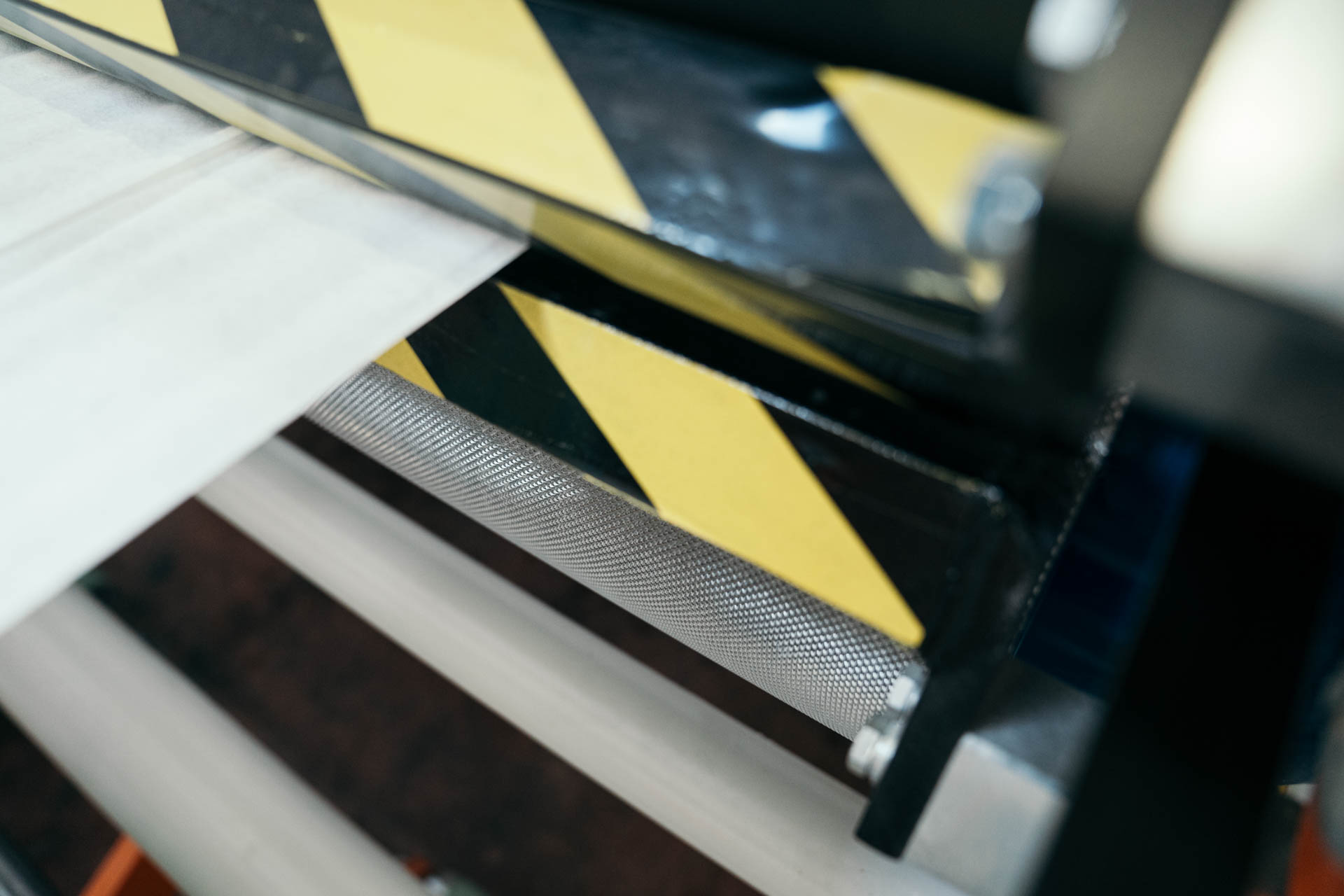

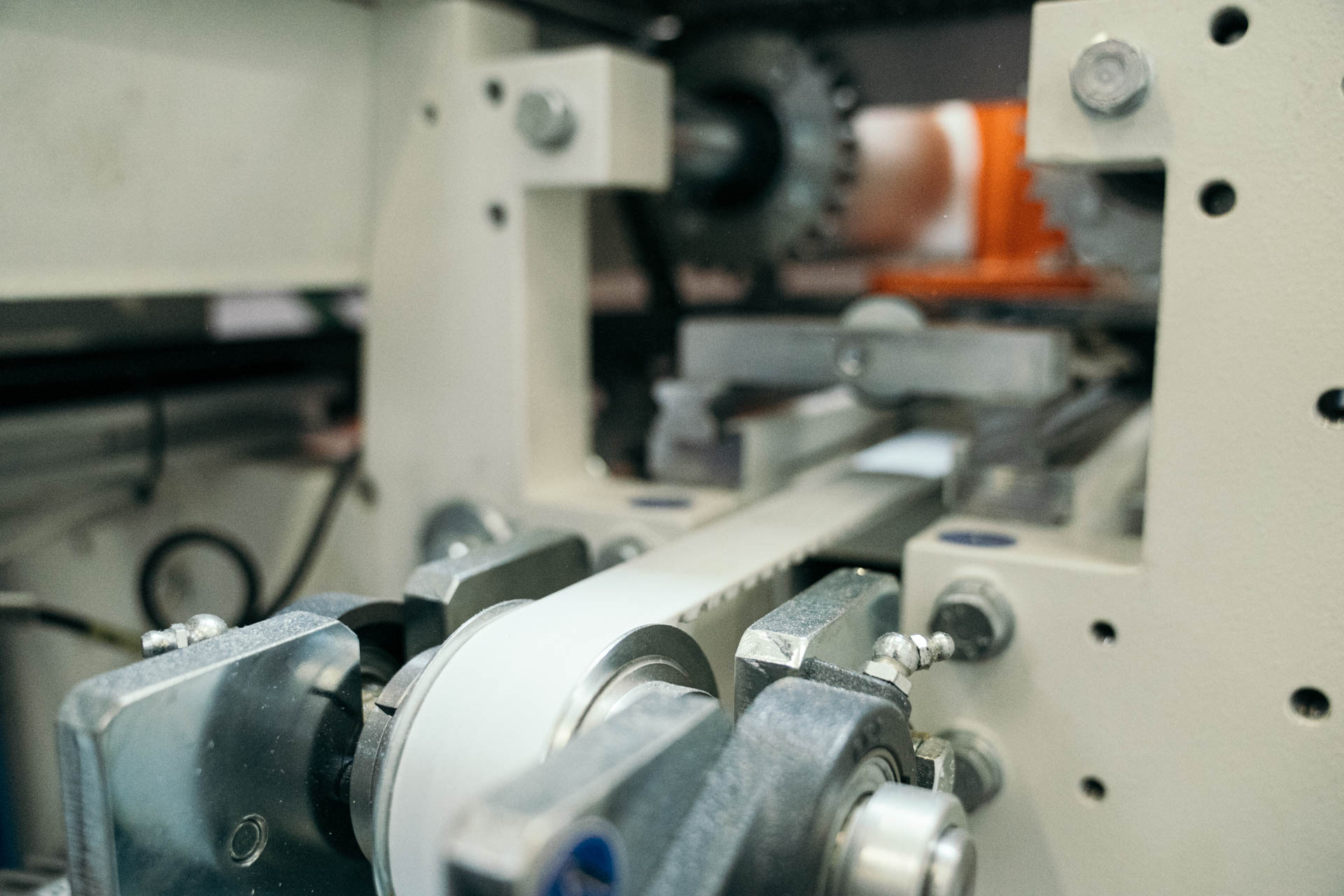

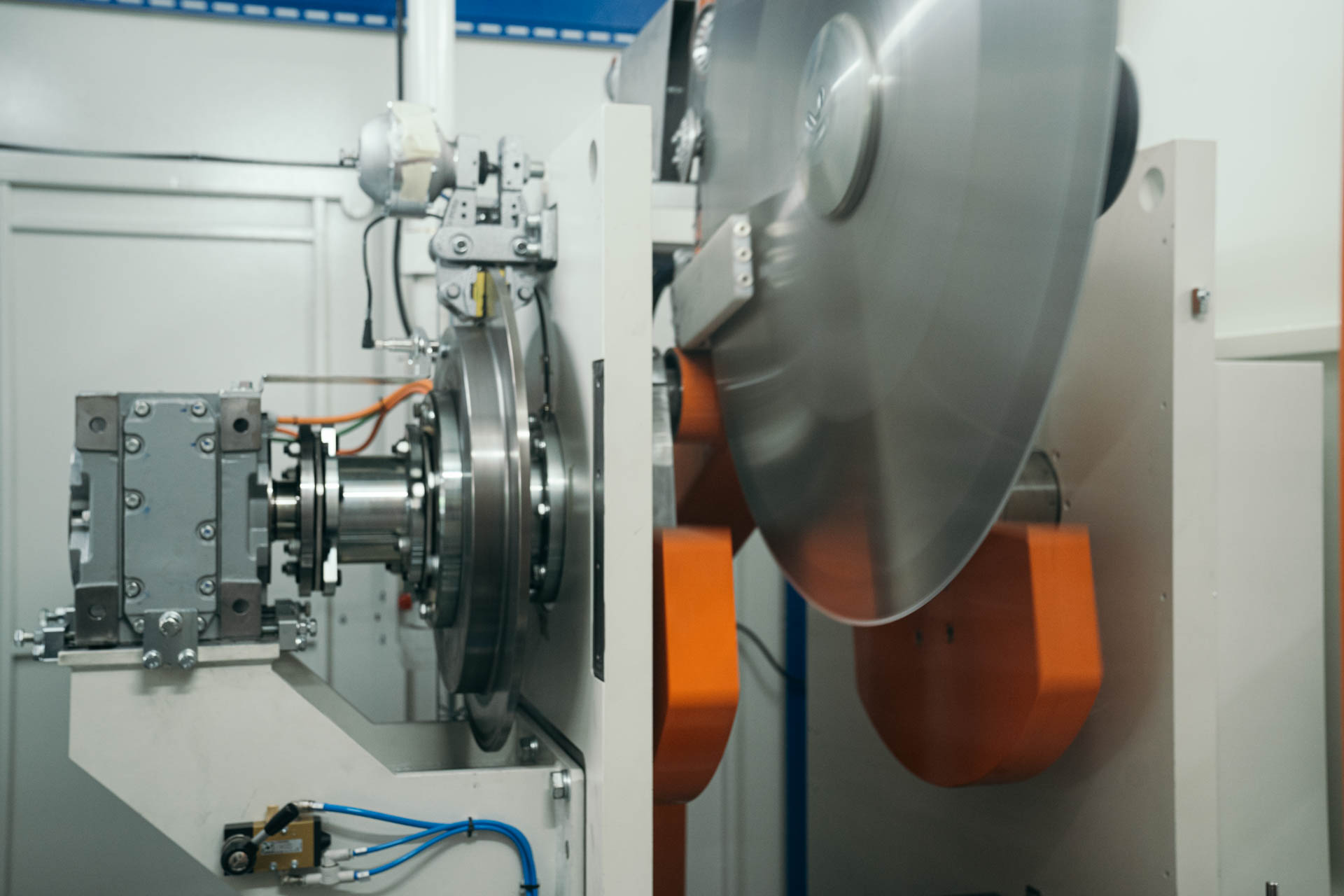

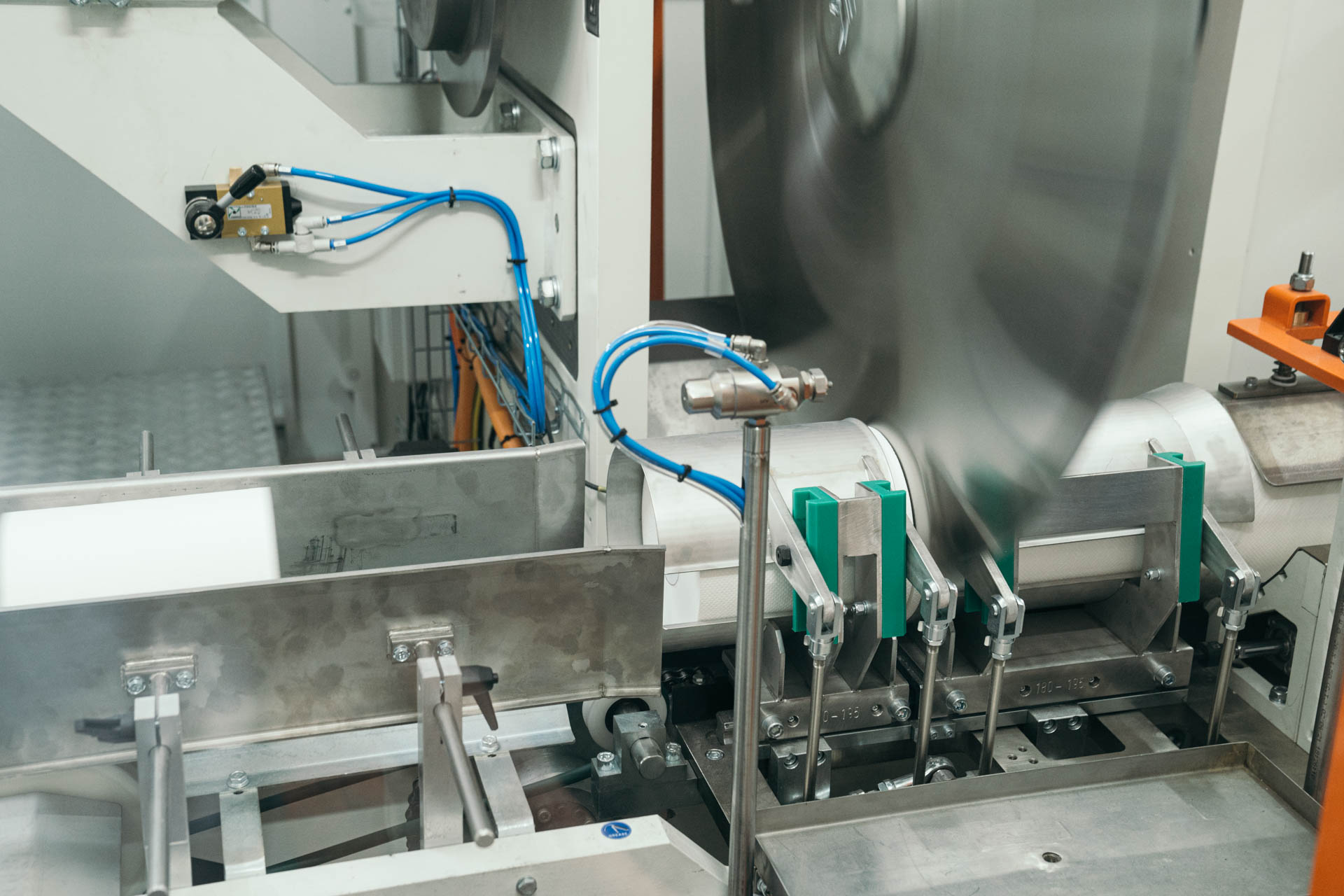

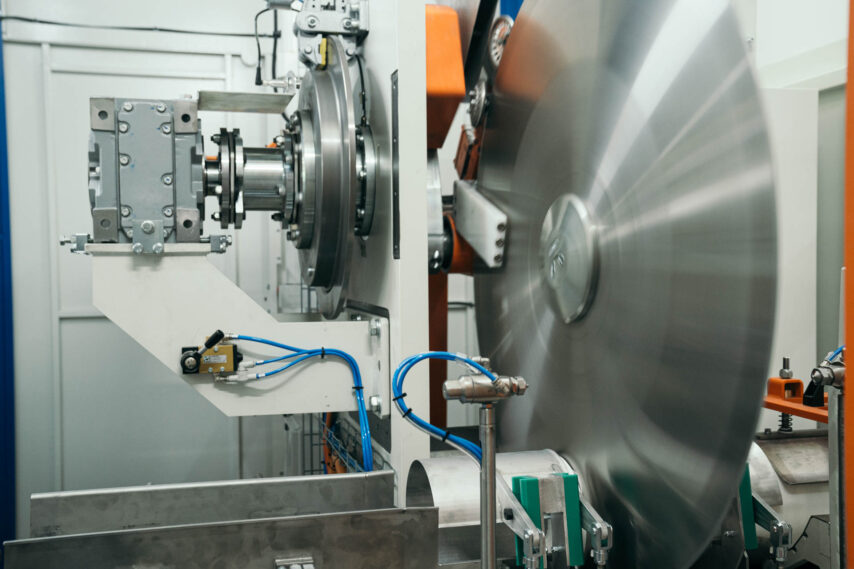

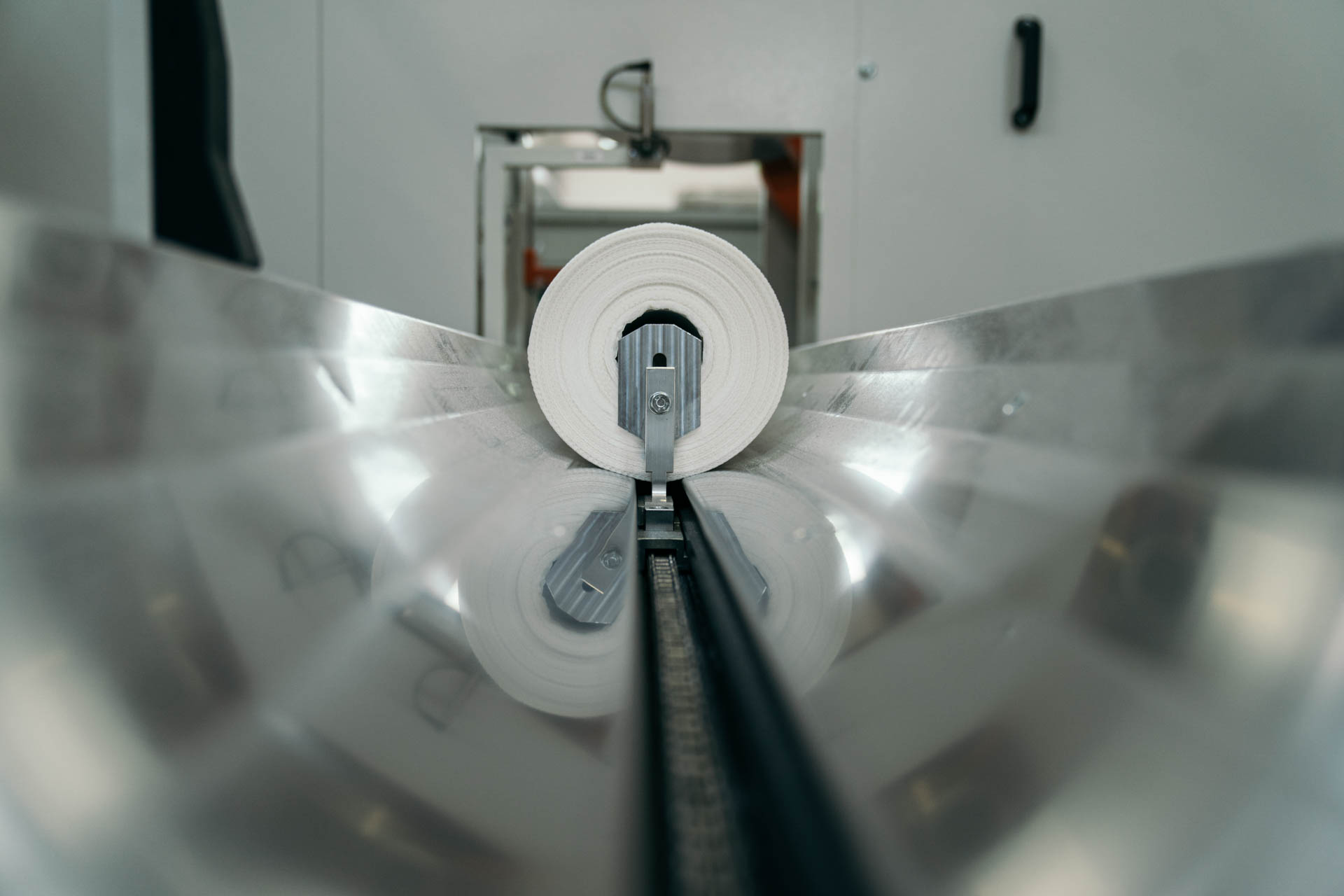

Flexible, high-performance, and easy to use, the S SERIES delivers 20% higher productivity with better winding quality than any competitor’s start-stop line. The design with direct independent motorization allows for the highest winding standards and energy efficiency. The latest generation servo-motors used on the S SERIES, which integrate a KERS (Kinetic Energy Recovery System), guarantee energy savings of up to 50%. Moreover, the servo motors also facilitate all settings and adjustments, performed through a simple Human-Machine Interface (HMI) panel, without the need for skilled operators.

Data sheet

- Production speed: from 600 to 700 m/min

- Core diameter: from 20 to 90 mm

- Log diameter: from 90 to 400 mm

- Modular structure

- Fully Servo driven

- Automatic Coreless (option)

- In-Line slitting unit (option)

- Nonwoven optimized configuration (option)

- Production: up to 5000 Tons/year

Advantages

- Increased production speed: +20% vs competitors

- Higher efficiency: up to +25% Overall Equipment Effectiveness (OEE)

- Improved product quality: superior winding consistency over the entire diameter

- Reduced energy consumption: with energy-saving KERS servo motors

- Lower operator skills required: all adjustments made from HMI (operator panel) and not with fine mechanical adjustments requiring skilled operators

- Lower skill requirements for setup and maintenance: the machine is controlled by servo motors and not by complicated belt and pulley systems requiring fine and complex adjustments

Related case studies

News

Subscribe to our newsletter

Get early news, updates and insights from UCT about the tissue converting world.

We are here to give you all the information you seek

Reach us if you want to know more, ask for support or get access to exclusive content.