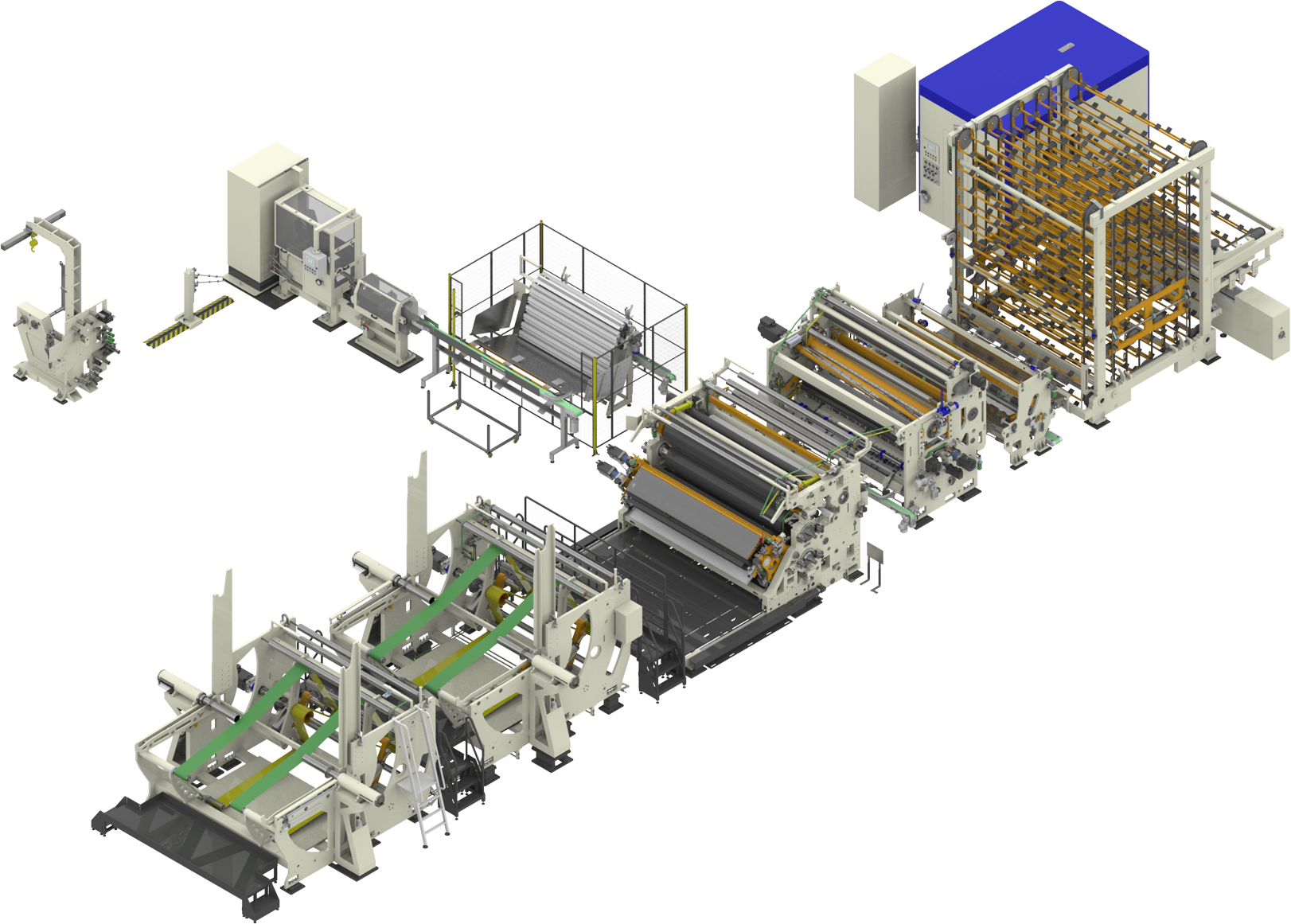

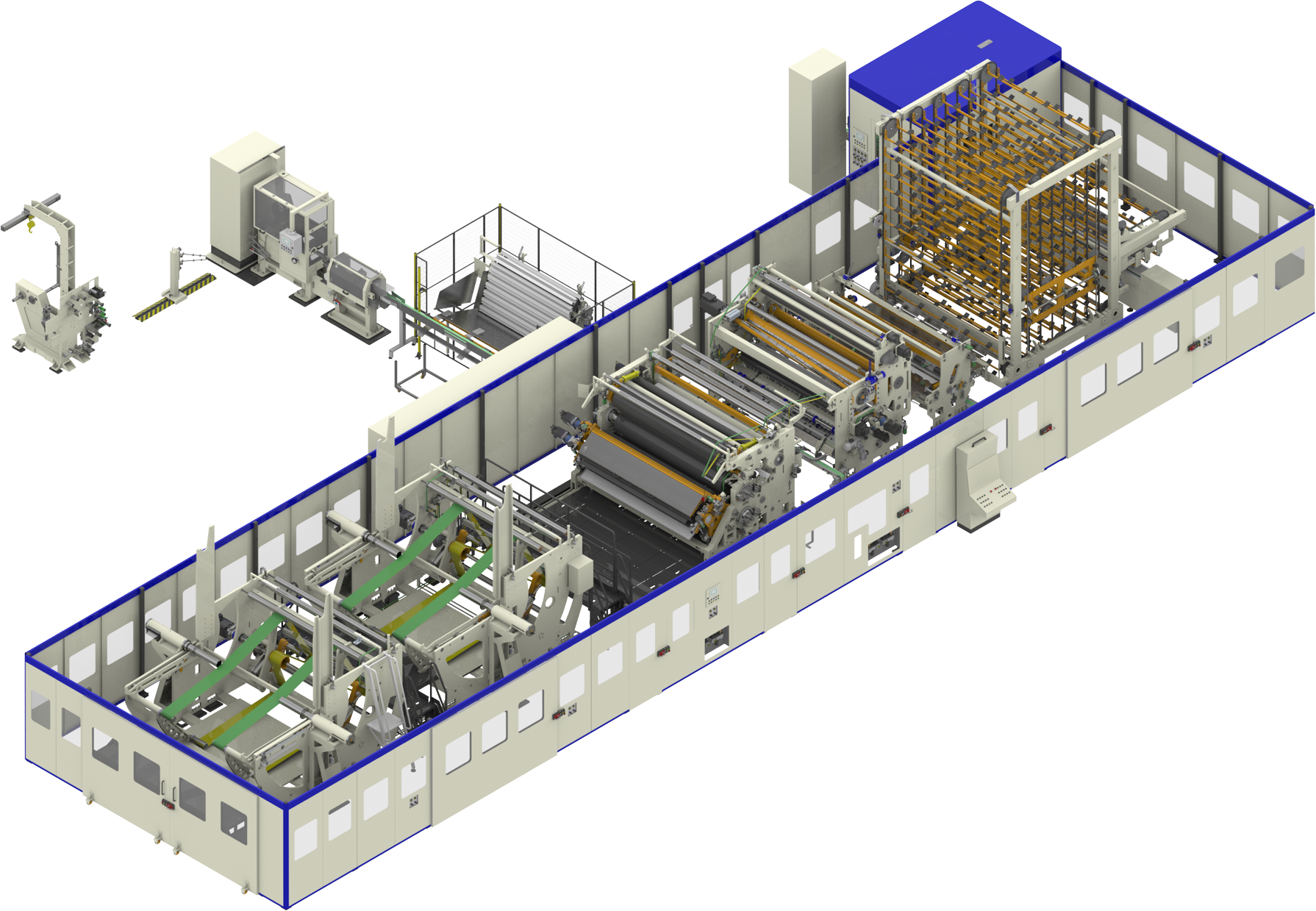

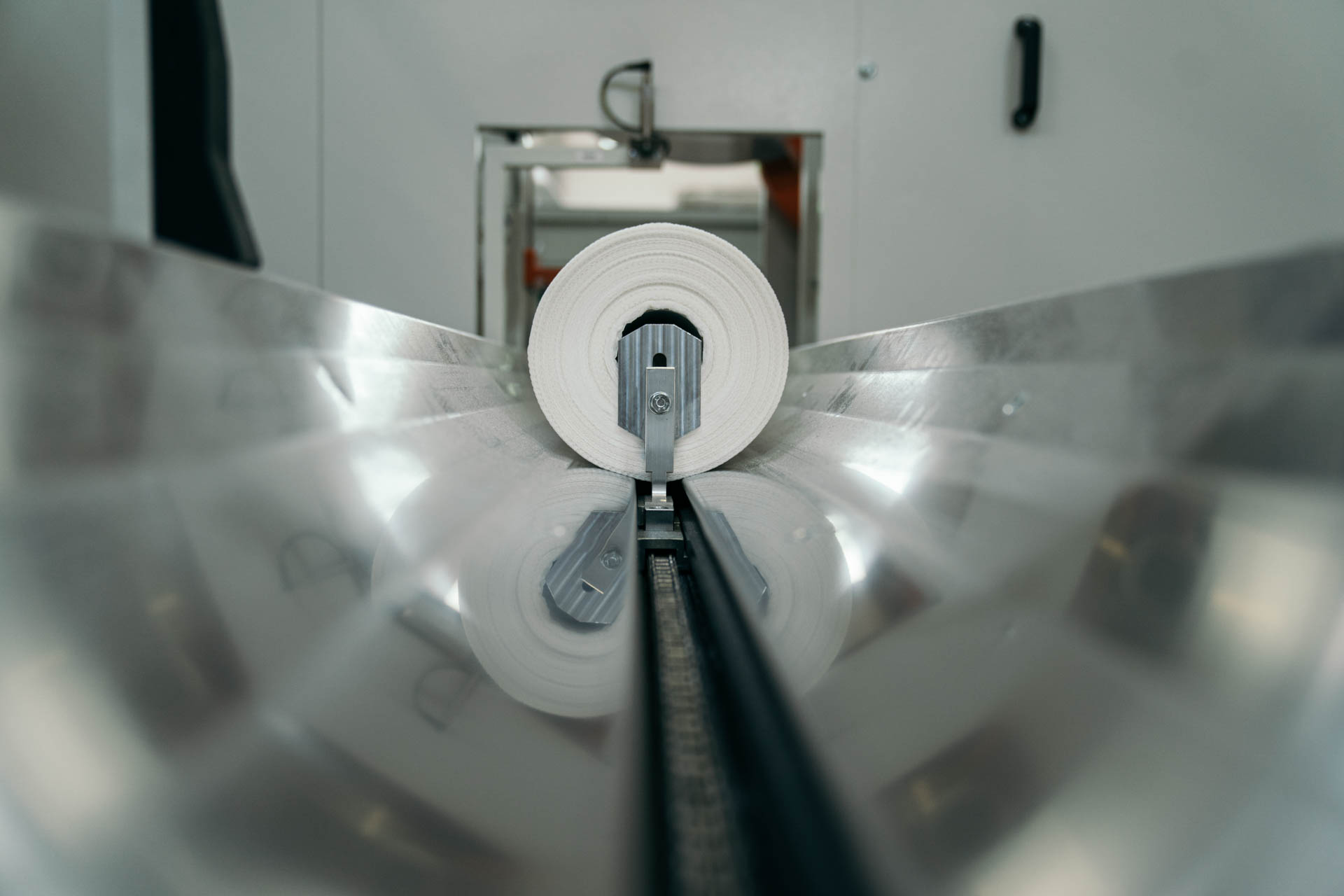

Coreless System

Developing technologies to meet Customer needs and drive their success.

Easy to use and reliable, Nexus i offers maximum production flexibility, allowing fast changes in paper type and finished roll product type.

The design with direct servo motorization, together with the patented automatic transfer system Airblade, allows operators to work at high speeds with simplicity, thanks to precise control of paper tension and a simple process management system. Intuitive and flexible, the technological choices on the Nexus i process are optimized for AFH products with specifically designed winding nests and a strengthened log support system capable of managing high bulk towels to high density, high diameter logs. AFH-Hybrid configuration available with variable winding nest geometry that enables an extensive cross-sector finished product range.

Get early news, updates and insights from UCT about the tissue converting world.

Reach us if you want to know more, ask for support or get access to exclusive content.