Nexus i

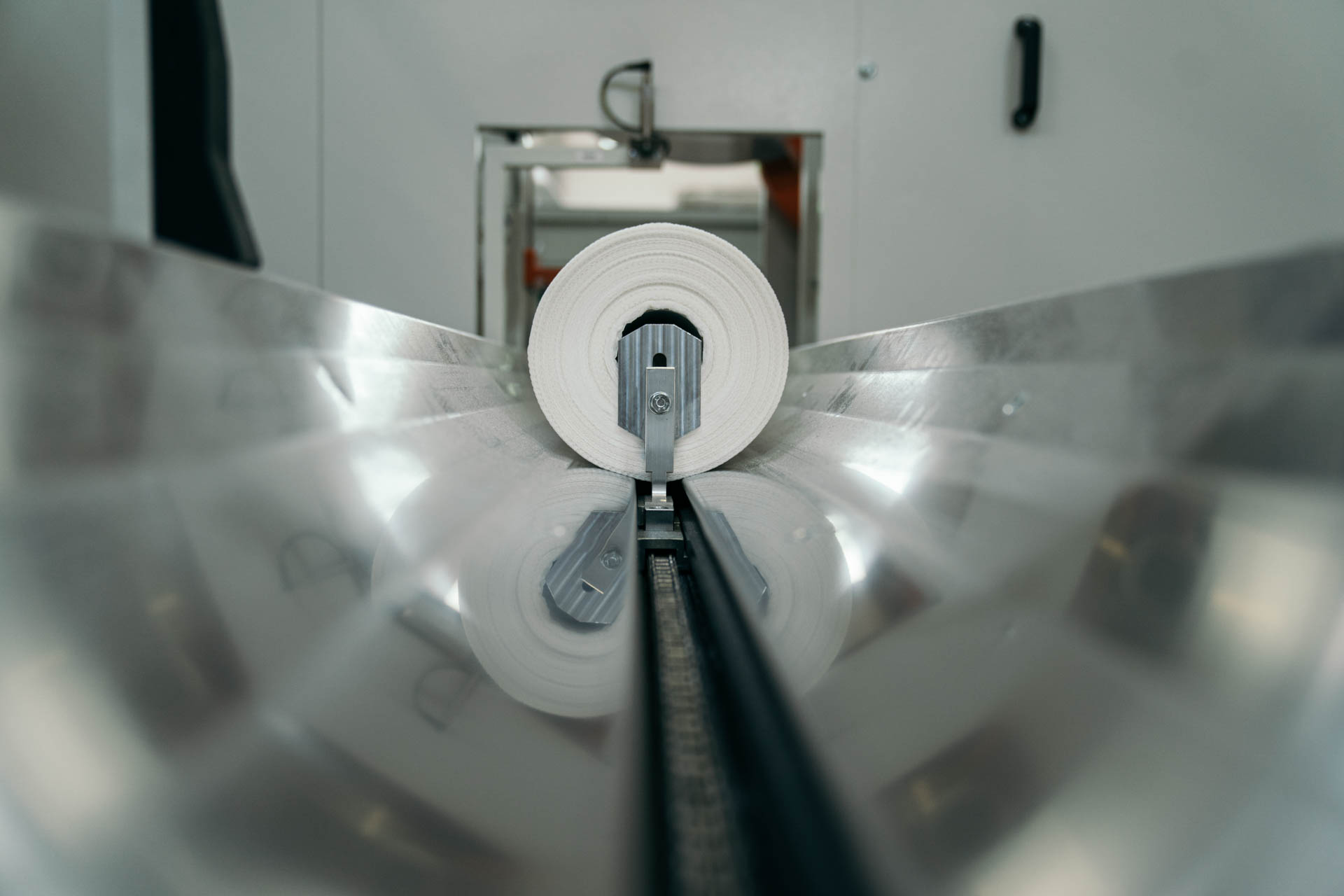

Easy to use and reliable, Nexus i offers maximum production flexibility, allowing fast changes in paper type and finished roll product type.

How simpler processes, not overcomplication can unlock efficiency in a converting line.

A new enquiry for a consumer line from a leading Far East manufacturing company presented the best opportunity to identify the type of projects where United Converting Tissue Nexus C lines are the best solution to improve competitiveness. The customer’s considerations for the final selection combined CAPEX and OPEX, evaluated as the Total Cost of Ownership (TCO), ultimately resulting in market competitiveness for the finished product in an industry where integrated paper mill-converting plants are taking the lead. The TCO evaluation considered expected production speed against nominal line speed, while also taking into account a larger number of factors, including OEE, simplicity of use, and maintenance.

The Nexus C line’s advanced automation and control systems significantly reduce the need for manual intervention, enhancing both safety and productivity. This automation ensures consistent product quality and reduces the likelihood of human error, which is crucial in maintaining high standards in the competitive market.

The United Converting Tissue Nexus line was chosen as the most balanced solution, with lower CAPEX options being penalized by higher OPEX in the long run, and higher CAPEX options unable to benefit from higher output due to SKUs matrix and raw material cruise speed limitations. Customer reports indicate they are currently operating 24/7 for 340 days per year at 86% converting line efficiency, rewarding the end user’s selection process.

Easy to use and reliable, Nexus i offers maximum production flexibility, allowing fast changes in paper type and finished roll product type.

Easy to use, flexible, and reliable, Nexus C is the ideal line for converters who want to speed up paper changing and setting operations according to the type of finished product.

Get early news, updates and insights from UCT about the tissue converting world.

Reach us if you want to know more, ask for support or get access to exclusive content.