S-Line

Boost your productivity and efficiency coefficients. S-Line is more efficient, more flexible, more sustainable, easier to use and maintain.

Simplicity at its best!

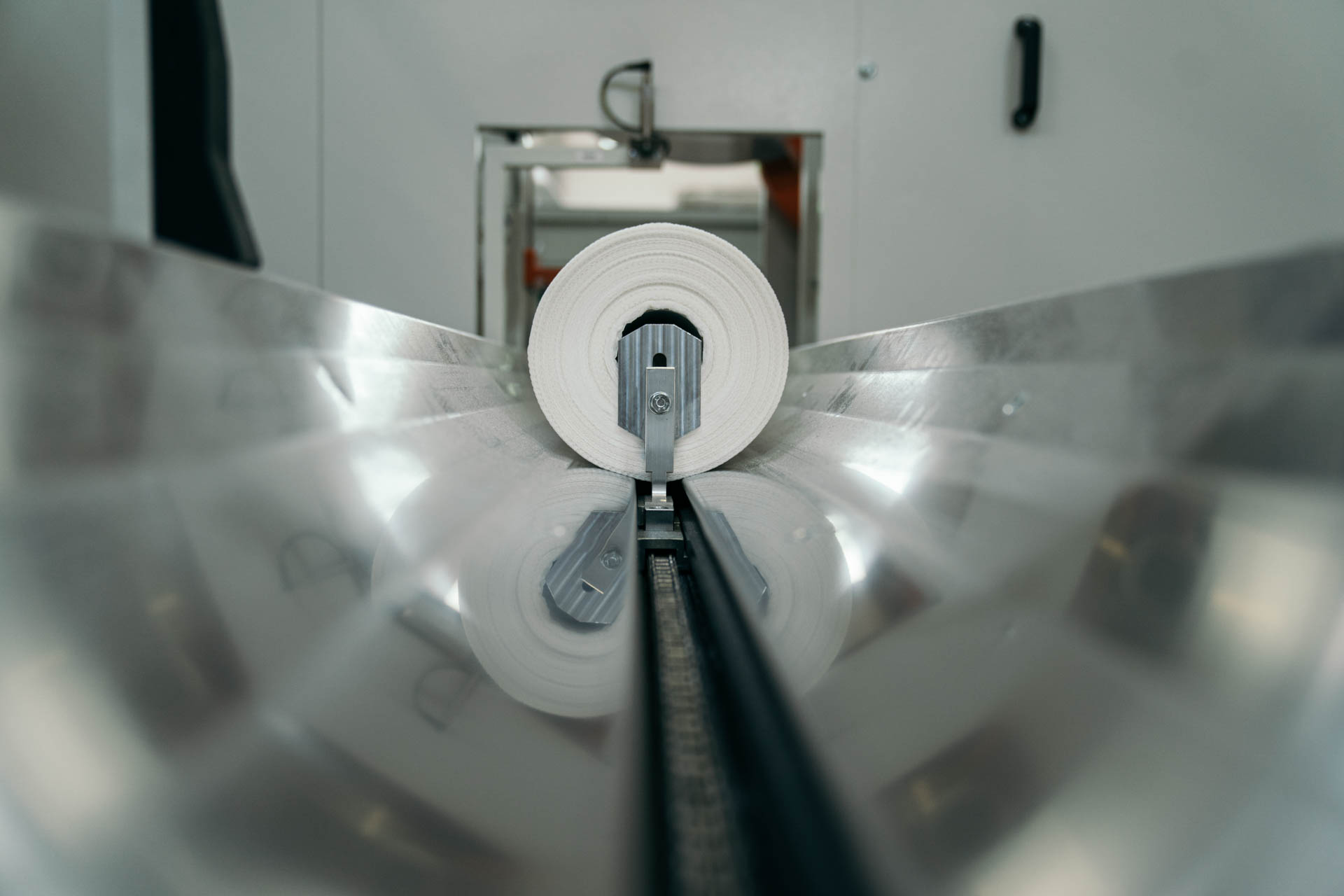

A family-run converting company operating several start-stop lines was experiencing a drastic increase in operator turnover and needed to optimize production. The capability to produce bespoke products on customer request in small batches was a key factor for the company’s success in the market. This led to the decision to invest in a new S60 line with a Unico365 Logsaw, aiming to replace two existing lines from other manufacturers. The United Converting Tissue start-stop lines are known to be the industry benchmark. Thanks to fully servo-driven technology, the line can convert higher quality products with a higher output than any other start-stop solution available on the market. Moreover, the integration with a Unico365 logsaw allowed the customer to move to the S60 Line the production of their best-selling product—a 1500 m by 350 mm diameter towel with a 300 kg/m3 density—that the customer was previously only able to make with slitting knives. This resulted in the final replacement of three converting lines with a United Converting Tissue S60, now used to convert more than 6000 tons per year.

Boost your productivity and efficiency coefficients. S-Line is more efficient, more flexible, more sustainable, easier to use and maintain.

Get early news, updates and insights from UCT about the tissue converting world.

Reach us if you want to know more, ask for support or get access to exclusive content.