Our design standards

Our research activity is guided by a series of quality standards that characterize the design of our converting lines:

Unico Lab is our ideas factory, the beating heart of our "Simplifying Tissue Converting®." A research and development department in which we constantly invest to support and train a group of engineers and designers capable of translating the trends and needs of the tissue industry into high-performing, cutting-edge, safe, sustainable, and above all easy-to-use solutions.

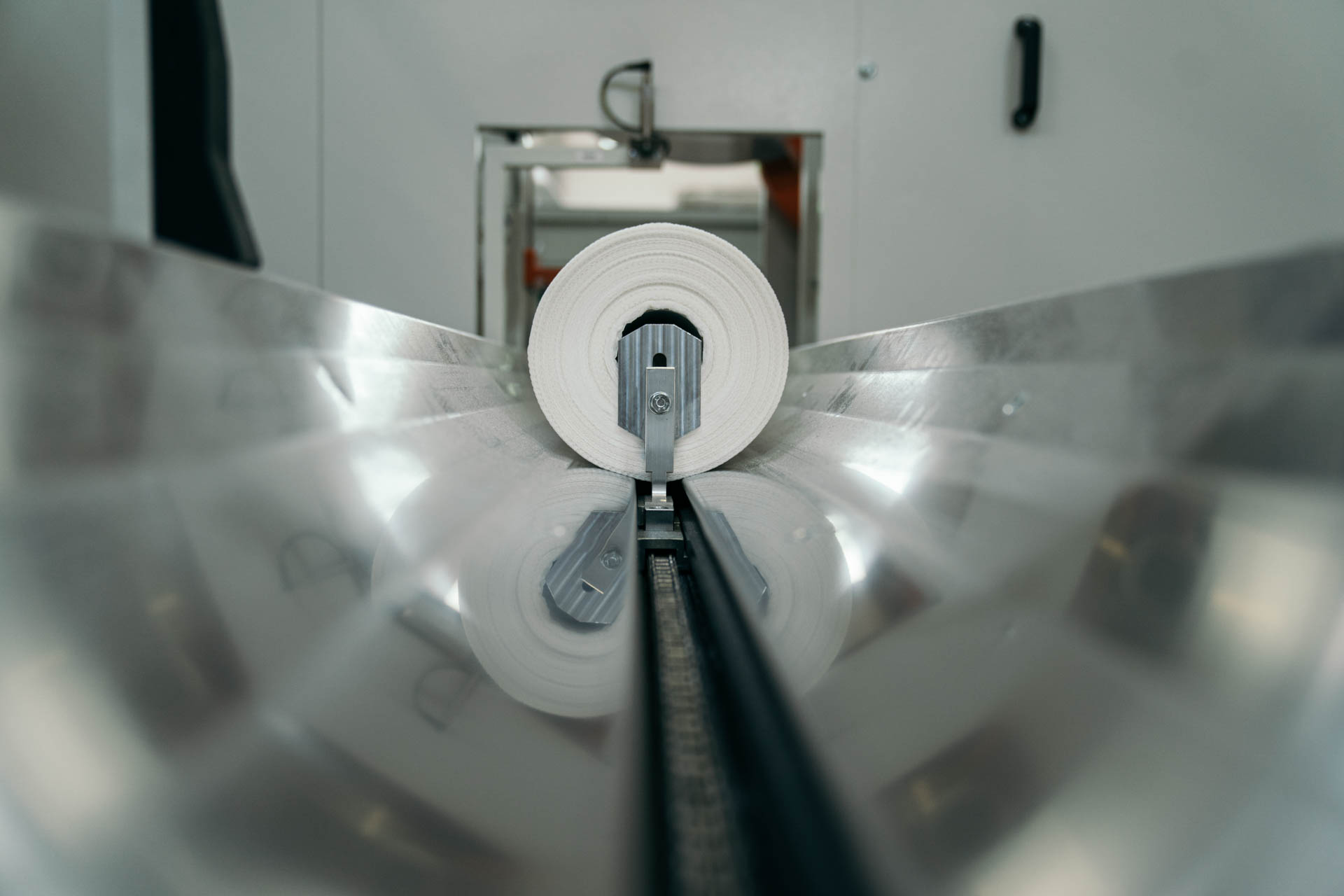

From Unico Lab have sprung our brightest ideas and all our patents: the UC AirBlade transfer technology without mechanical components subject to wear, fully controlled by the human-machine interface (HMI), and integrated into the Servo-Driven-Approach (SDA) system; the UC Unicore winding technology that enhances machine usability, winding quality, and reliability; Unifold, the transfer technology with a vacuum system that improves folding precision and facilitates maintenance; Unitransfer, a system designed to improve production efficiency and finished product quality; Unico365, one of the highest performing logsaws on the market in terms of speed, quality, and maximum cutting density, mechanical wear reduction, blade change simplicity.

Our research activity is guided by a series of quality standards that characterize the design of our converting lines:

Our drive towards innovation is based on the experience and exclusive know-how of our professionals and is realized in the development of high-performing and easy-to-use technological solutions.

Our converting lines are not only innovative but also versatile, capable of guaranteeing the production flexibility necessary today to remain competitive.

Our converting lines are built with reliability in mind, both for the finished product, which must maintain its distinctive characteristics over time, and for technological components and spare parts, which must ensure constant performance.

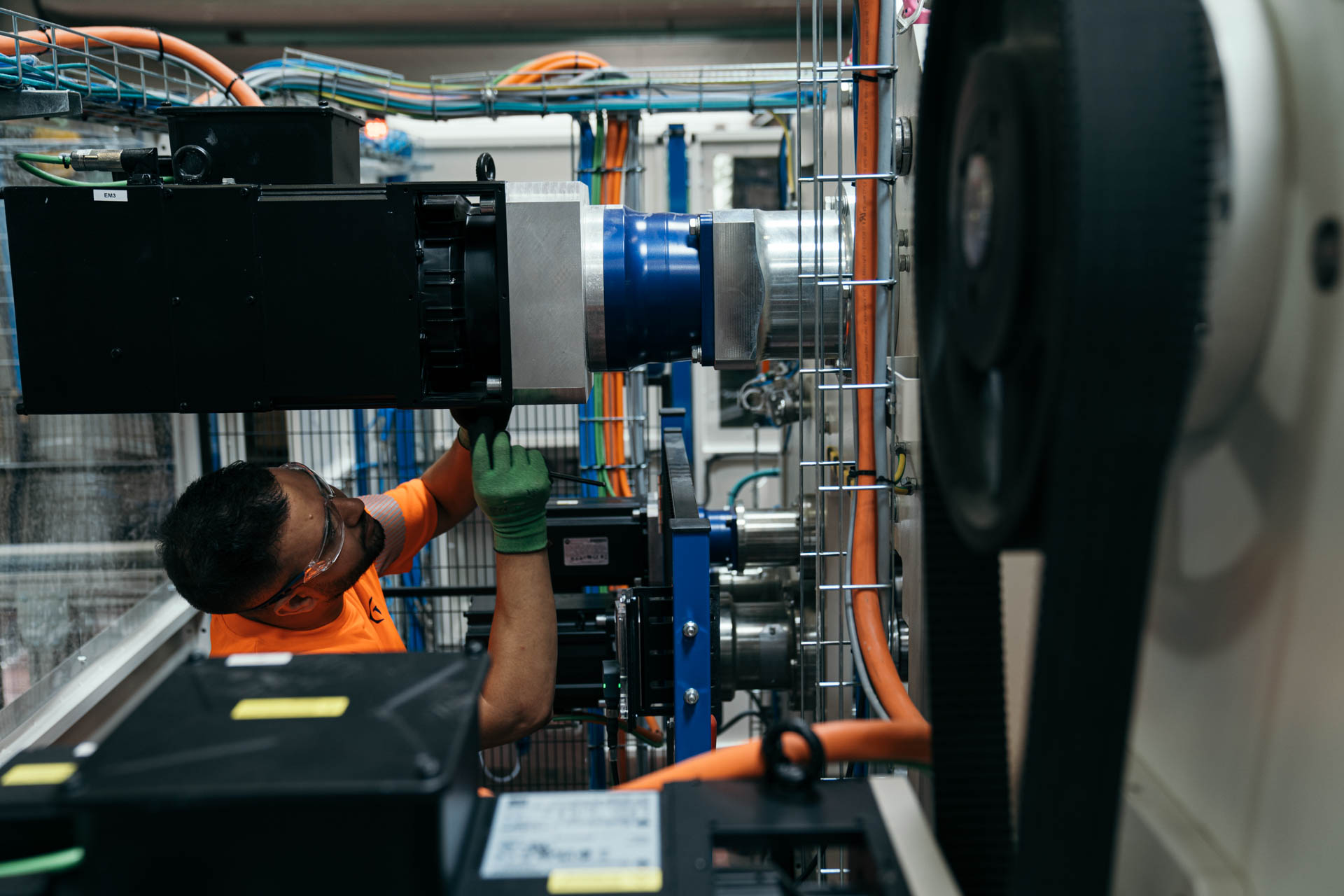

Energy efficiency is one of our flagship features. Our lines mount high-efficiency servomotors and reducers to reduce consumption and total energy footprint.

The innovation we pursue is aimed at improving processes and raising the quality of your finished product to enable you to distinguish yourself over time from your competitors with the highest standards and at the lowest possible cost.

Simplifying industrial processes is not an end point but the beginning of a journey. That's why we will always be with you and your lines, following both over time to be ready to understand and transform your needs into simple and effective solutions.

Timeline

Over the years, we have grown, opening branches in Europe, Asia, and the United States. Our team has grown, as has our turnover. Nevertheless, we love to trace our history through the milestones of our product innovation. A story that has its roots in our engineering department and our workshops, the nerve centres of our company.

United Converting Tissue is born.

UCT designs the start-stop rewinder S60 around which it launches the first and only fully electronic automated line on the market up to that point and opens a foreign commercial branch in the United Kingdom, UCT UK LTD.

UCT develops its first prototype of automatic rewinder: the Nexus line is born.

UCT develops and patents the Airblade transfer technology, the most efficient, flexible, and reliable transfer system still on the market today.

UCT develops and patents a new automatic transfer system for folding machines: Unitransfer, which improves production efficiency and finished product quality.

UCT develops the upgrade of the Airblade transfer technology.

UCT develops and patents Unifold, a new frictionless vacuum application concept around which it develops and launches its first interfolding machine on the market: Vista 200.

UCT develops and patents the new Unico365 Clamping System, which redefines performance parameters in the logsaw sector, and the innovative Unicore system, a new, more efficient, flexible, and reliable transfer system with which the new Nexus automatic rewinders are equipped.

Born and raised in the heart of the Tuscan Tissue Valley, we have developed a series of tissue converting lines, both in roll (AFH or Consumer) and folded (Towel or Facial), that are high-performing, reliable, flexible, easy to use, maintain, and configure according to your needs and market.

Optimizing and making a tissue converting line more efficient doesn't just mean ensuring higher performance, but also adopting intelligent technologies to improve the quality of your products and the productivity of your team without the need for long and complex training processes.

Get early news, updates and insights from UCT about the tissue converting world.

Reach us if you want to know more, ask for support or get access to exclusive content.